Honda South Carolina Manufacturing rolls 500,000th UTV off the line

Honda South Carolina Manufacturing (SCM) marked a major milestone on August 6 with the production of its 500,000th side-by-side vehicle. The landmark unit — a Pioneer 1000 — rolled off the line during a plant-wide celebration, underscoring the facility’s role as the exclusive global production site for Honda’s SxS lineup.

The 950,000-square-foot Timmonsville facility opened in 1998 to build the Honda Foreman 400 ATV, adding ATV engine production in 2000 and Honda AquaTrax personal watercraft in 2003. Side-by-side production began in 2013, and SCM now produces all models in Honda’s Pioneer platform and Talon sport family. However, Honda ATVs have since been moved to a production facility in Swepsonville, North Carolina.

Over 27 years, SCM’s nearly 1,000 associates have produced more than 3.8 million powersports products and driven over $460 million in capital investment, according to Honda. The plant’s output has supported Honda’s dealer network across North America and global markets, helping meet the rising demand for recreational and utility side-by-sides.

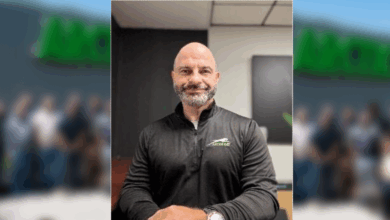

“I’m extremely proud of our team in Timmonsville,” says Travis Lee, SCM site lead. “Their commitment and passion are the reason we’ve achieved this milestone and many others over the years. No matter where our associates are in their careers at SCM, they are part of our success.”

To commemorate the occasion, associates gathered at the end of the line as the 500,000th Pioneer 1000 was driven by 24-year Honda veteran Glascow Montgomery. Starting in machining in 2001, Montgomery has sent countless vehicles down the line, but said his focus has never changed.

“I want to make sure these units are perfect for our customers. When the unit makes its way to me, I’m listening to the engine, testing the steering wheel, and checking the lights—it’s important to me that we do things right.” — 24-year Honda veteran Glascow Montgomery.

Looking ahead, Honda says SCM will continue to invest in smarter, more efficient manufacturing practices and prepare for future electrification.