FLY Racing unveils a new standard in helmet protection

FLY Racing on Thursday in San Diego revealed its all-new Formula helmet, one of the most advanced motocross helmets ever created after years of collaborated research and design with industry leading doctors, scientists and physicists from around the world.

Most traditional helmets only provide protection from a very narrow range of impact scenarios. FLY Racing’s goal with the Formula was to go beyond this and provide superior head protection from the widest possible range of potential real-world impacts. The result is a technologically advanced helmet engineered with an inside-out philosophy. Utilizing a fine-tuned ecosystem of structural designs and energy mitigating materials, the Formula will redefine helmet performance and safety expectations.

Tested under rigorous scientific standards that replicate real world conditions, the Formula outperformed all helmets tested in both high velocity impact crashes as well as forces created by rotational and low speed impacts.

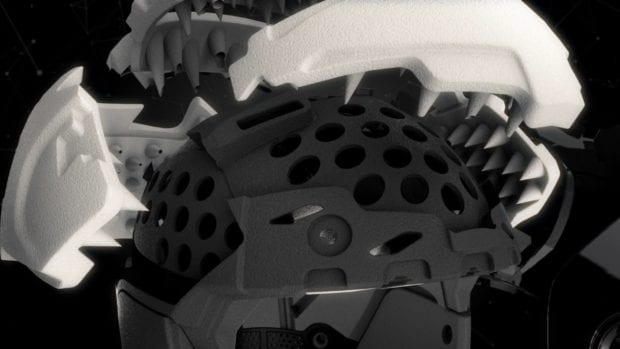

Adaptive Impact System (AIS)

FLY Racing’s Formula Helmet is the absolute in total head protection. The Adaptive Impact System (AIS) is a high-performance ecosystem of structural design and energy mitigating materials.

Each layer of the AIS from RHEON enhanced Energy Cells, to the dual-density EPS liner, and the 12k carbon fiber shell, was carefully fine-tuned to achieve the goal of creating the highest performing helmet possible.

Energy Cells Enhanced By RHEON

Impact Energy Cells were engineered by the FLY Racing design team specifically for the Formula. The seven strategically-placed cells in the EPS liner are designed to feel natural inside the helmet, resulting in a seamless fit for the rider. Their unique shape and maze-like structure allow the Impact Energy Cells to compress and shear. Each cell can either compress during a linear impact or shear during a rotational impact. This slight movement maximizes absorption of low speed linear and rotational impacts reducing overall brain stress.

These energy cells are made of RHEON, an “active” strain-rate sensitive material that efficiently absorbs and dissipates energy as it deforms. Invented by Dr. Dan Plant, a mechanical and industrial design engineering expert based at the Imperial College of London, RHEON’s adaptive chemistry reacts instinctively to control energy and change its behavior depending on the severity or direction of an impact. Essentially, the RHEON Impact Energy Cells maximize absorption of low speed linear and rotational impacts.

“Since you can’t predict how you’re going to fall, RHEON’s unique and intentional geometry also controls the impact energy coming at you from any direction, whether its linear or rotational,” Dr. Plant

Conehead Technology

Like a crumple zone, Conehead technology absorbs and dissipates impact forces more effectively than traditional EPS helmet liners. Created by physicist Don Morgan, Conehead technology uses cone shapes to pair a firm density EPS with a much lower density EPS. The result is more progressive energy absorption through a broader range of impact scenarios.

The Formula has six critical zones of Conehead EPS. Each zone has a uniquely fine-tuned combination of EPS densities to manage impacts specific to that region of the helmet. These specific multi-density EPS zones produce a much more progressive response to low speed and high-speed impacts.

Expanded EPS

Studies have shown that the majority of impacts occur on the forehead or side of the head. To help combat these impacts, the Formula development team incorporated lower density expanded volume EPS (thicker EPS) in these critical zones. This expanded volume EPS provides improved suspension for impacts.

12K Carbon Fiber Shell & Control Release Visor System

The Formula’s first line of defense is an extremely strong and lightweight 12K carbon fiber shell. 12K carbon fiber refers to 12,000 carbon filaments per band. Carbon fiber is strongest when it is flat. Wider carbon fiber bands woven together produce a flatter result with less dips and rises inherent in a woven material. The reduction of these dips and rises creates less areas for resin to pool. Less resin equals less weight. The result is an extremely lightweight shell with superior penetration resistance to common 3K carbon fiber.

Mounted on the front of the helmet is a durable yet flexible fracture resistant nylon visor. FLY’s own proprietary Control Release System secures the visor to the helmet but will allow it to release under certain types of impacts.

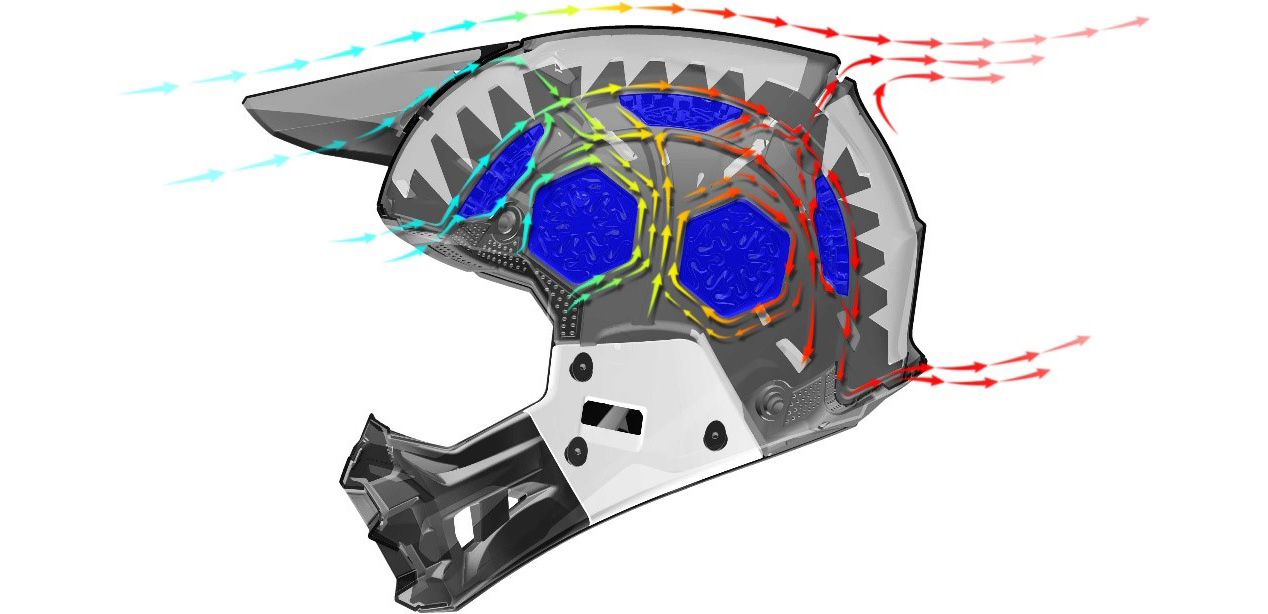

TRV Functional Ventilation

True Functional Ventilation (TFV). When in motion cool air is forced through multiple air intake vents. It then passes through vent channels in the EPS to collect the heat inside the helmet. Finally, the heat is literally sucked out through multiple exhaust vents. This suction is the result of a venturi effect created by the unique geometry of the helmet. The increased draw of air out of the rear of the helmet significantly boosts overall air movement and cooling.